Electronic cigarette case

Product Information

FOB Price:US $0.5 -8 / Piece

Min.Order Quantity:500 Piece/Pieces

Supply Ability:20000-50000Piece/Pieces per Month

Delivery Location:Ningbo

Material:Aluminum/Zinc

Warranty:2 Years

Payment Terms:L/C,T/T

| Product Name | High pressure aluminum die casting Oil Boat Motor Housing 2 parts |

| Dimensions | As customer’s requirement |

| Service | OEM |

| Export Market | Global |

| Certification | TS16949(2009) |

| Tolerance | +0.001mm |

| Weight | 0.02-20kg |

| Delivery Detail | Within 45days after received 30%deposit |

| Die casting materials | Aluminum alloy, A380, AlSi9Cu3, ALSI12,ADC12, ZL102and EN2500 |

| Quality | Step 1, Raw material check by spectrometerStep 2, in process check after die casting by X-rayStep 3, finished products check by CMM and special gaugeStep 4, pre - shipment check on packaging |

| Mold material | MS8407 mold steel |

| Mold hardness | 48~52HRC |

| Mold life | 500,000 molds |

| Surface treatments | High quality polishing, Shot blasting, chrome/nickel/zinc (white, blue, yellow, black)plating,hot galvanized, painting, powder coating, anodizing, electrophoresis and sandblasting |

| Software | Pro/E, Auto CAD, UG |

| Process | Drawing & Samples → Mold making → Die casting → Deburring → in-process inspection→Drilling and threading → CNC Machining → Polishing → Surface treatment → Assembly → Quality inspection → Packing → Shipping |

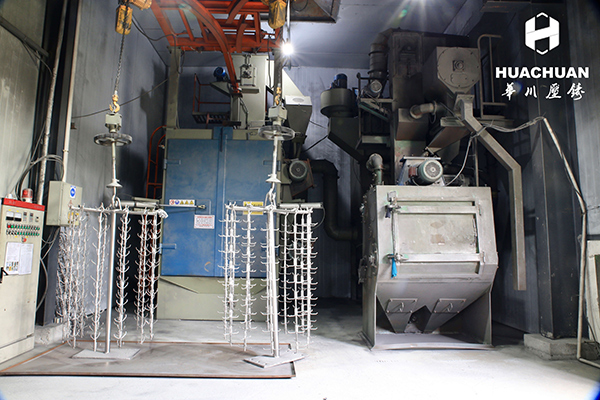

| Production machines | 4 pieces 280T-480T die casting machinery,20 sets of vertical machining center and edge cutting machine, sawing machines and sand blasting machines,15 sets of CNC lathes and other post-processing equipment |

| Inspection equipment | Coordinate measuring machine, largescale aluminum material direct reading spectrometer and various special inspection guages and tools. |

| Customization | Yes |

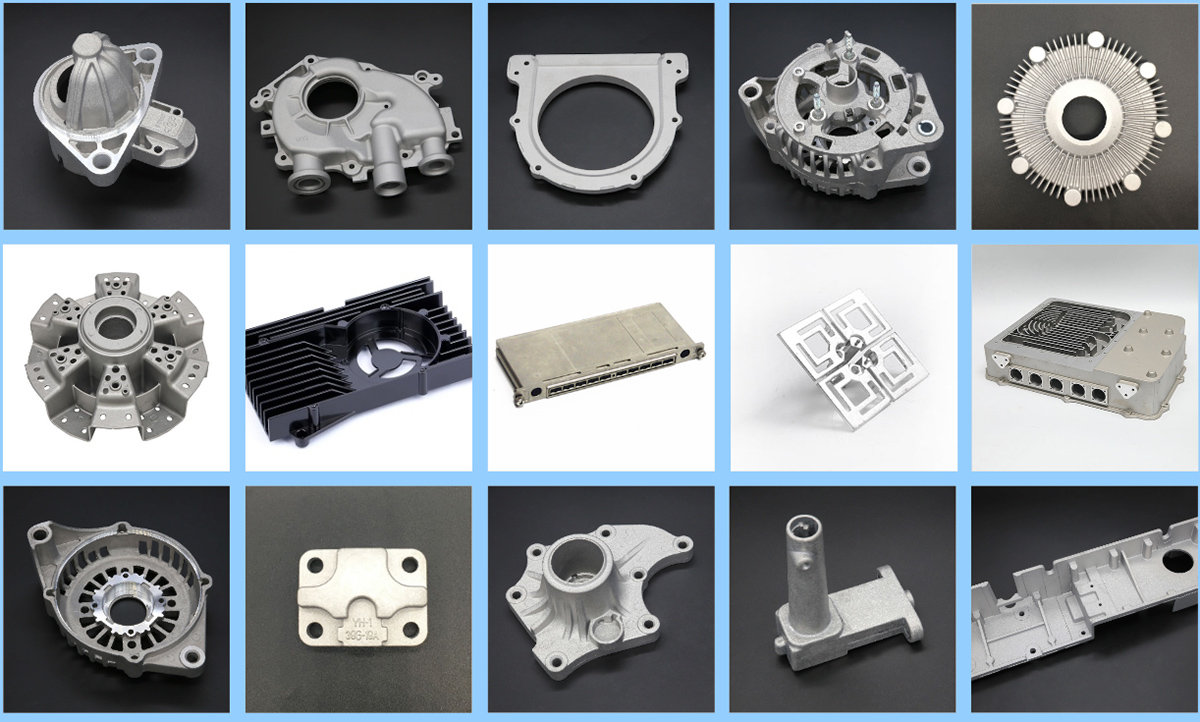

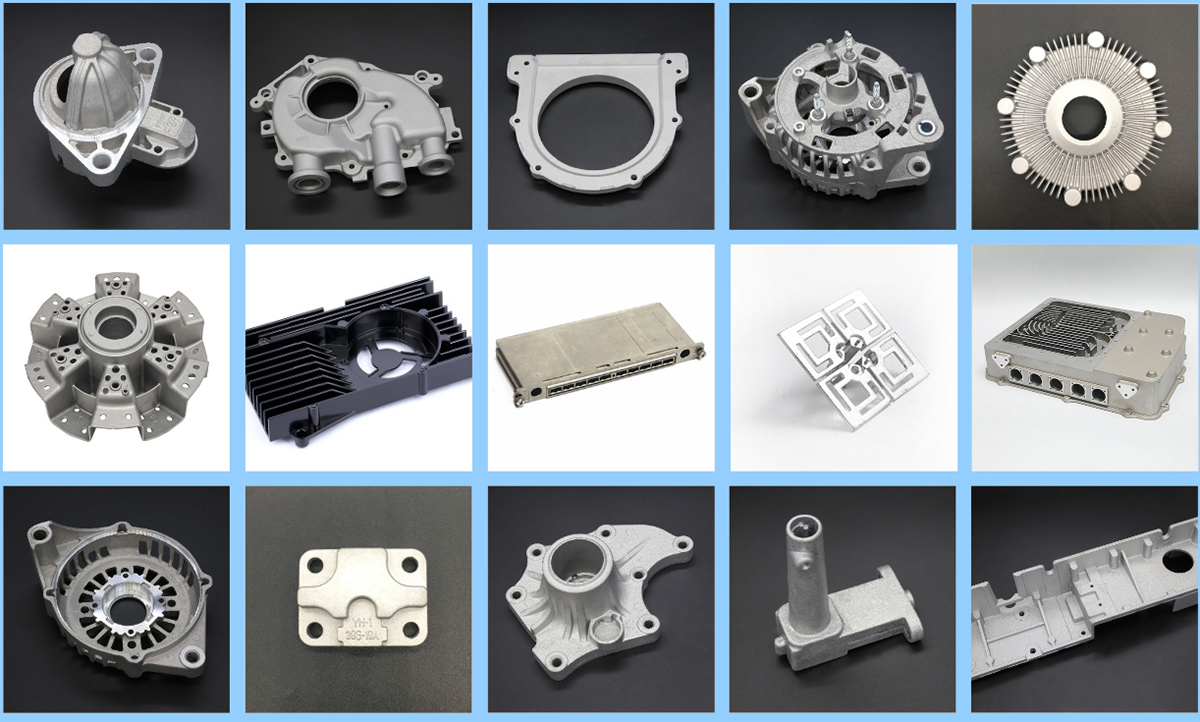

| Application | Air Blower Parts, automotive power systems, motorcycle engine parts, boxes for gasoline engine and deisel engine,cylinder cover, LED lighting cover,lamp covers ,supports, electrical equipment parts, communication equipment parts, etc. |

Professional supplier of aluminum alloy parts in Southwest China

Provide customers with worry-free and satisfactory services at high prices for 17 consecutive years

Customer First· Quality First·Honesty·Pursuit of Excellence

Auto and motorcycle parts

Electrical parts

Communication equipment

Lighting equipment housing

Digital Electronics

Industrial aluminum parts

Experienced

17 years of industry experience

Certification

ISO9001 certification factory

Post-processing

Finished product from blank to machining and surface treatment

Customer

30 enterprises witness

500 product experiences

Guarantee

500,000 pieces per Mpnth without delay in quality and quantity

Competitive Advantage of Huachuan Die Casting

5S service concept

17 years of high-quality worry-free after-sales service, allowing customers to save money, time, peace of mind, effort, and excellence.

Good price and good quality

Adhering to the win-win situation between customers and the company. Huachuan has provided customers with aluminum alloy parts with good prices and high quality, reducing customer product costs.

Extensive experience

The company was founded in 2003 and has been focusing on the production and technology of die casting of aluminum alloy parts.

Mold design&production

Senior product development engineer, mold designer team, high-quality precision mold design customization, processing and production

Equipment Management

Huachuan takes "quality first" as the principle and strictly manages according to ISO9001: 2015, so that the technical level, die casting quality and product quality are guaranteed.

Delivery on time

One-stop service for mold, die-casting, CNC processing, tapping, polishing, and surface treatment, stable quality, accurate delivery without delay

Workshop

Product

Company Profile

Dujiangyan Huachuan Die Casting Co., Ltd. (ISO 9001: 205) was established in 2003. It covers an area of 7,600 square meters and has a production area of 5,000 square meters. It is located in Chengdu, Sichuan. Combining die-casting manufacturing, machining and surface treatment of aluminum alloy comprehensive integrated professional die-casting enterprise in southwest of China.

The company is committed to designing and manufacturing aluminum alloy die-casting parts for automobiles and new energy vehicles, motorcycles, home appliances, LED lighting housings, communication equipment, electronic pulse valves and many mechanical applications. The company has various tonnage die-casting machines, CNC machining centers, CNC lathes, various surface treatment equipment and other various processing equipment. The annual production capacity of die casting reaches 3,000 tons.

The company is guided by customer needs, based on high and new technology, guaranteed by excellent quality, guaranteed by reliable reputation, with the tenet of "integrity, quality, hard work and service", and the goal of supplying high-quality products and services at reasonable prices and on time. Welcome Clients at home and abroad visit and cooperate!

F&Q

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of design and production

Q: Do you make custom products or finished products?

A: All parts are not in stock and can be customized according to customer drawings or samples! If you want to make any parts, please feel free to send us your physical drawings / samples.

Q: Will my drawings be safe after I get them?

A: Yes, we will not publish your design to third parties unless we have your permission.

Q: What is the MOQ?

A: Usually we do not set a minimum order quantity, but the cheaper the cheaper. In addition, we are happy to provide customers with prototype parts or samples to ensure quality standards.

Q: Can you cast from our samples?

A: Yes, we can make measurements based on your samples to make drawings for tooling.

Q: Can your company provide finished parts?

A: Yes, we can provide finished parts from aluminum alloy die casting rough parts production and CNC machining to surface treatment.